The challenges of global agricultural irrigation

Water shortage: According to data from the United Nations, agricultural water consumption accounts for over 70% of the total freshwater consumption worldwide. However, frequent droughts and over-exploitation of groundwater have led to a continuous decline in available water.

Rising energy and labor costs: Traditional flood irrigation or timed irrigation relies on on-site manual operation, and electricity, oil and labor expenses have been increasing year by year.

Pressure on crop quality and yield: Population growth demands a 20-30% increase in yield per unit area, while water shortage and overirrigation causing salinization and pests and diseases are eroding the quality of cultivated land.

Stricter regulation: The European Union, North America, Australia and other regions have successively enacted laws requiring farms to report data on water consumption, drainage volume and fertilizer loss. Traditional irrigation methods are difficult to provide accurate and traceable data.

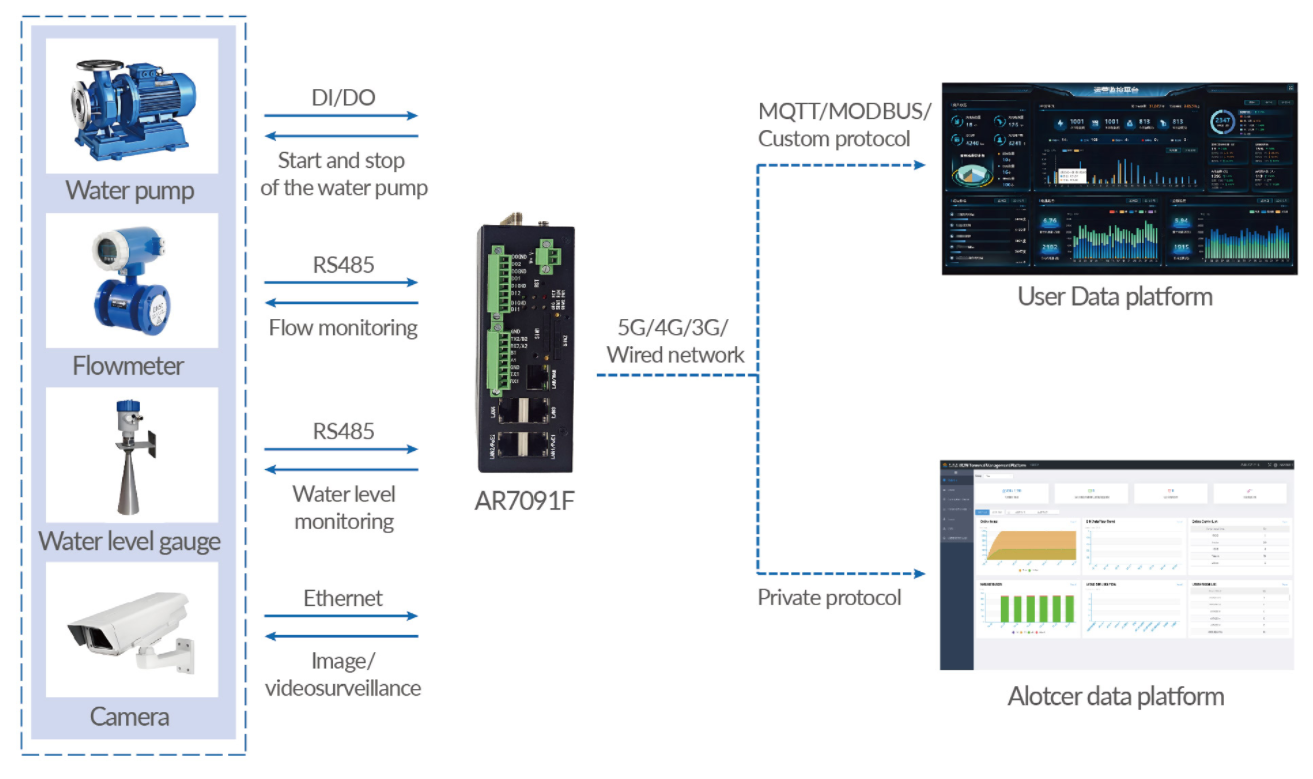

System topology diagram

System composition and principle

Water pump: It is responsible for pumping water for irrigation and is the main power equipment for irrigation

Flowmeter: It is responsible for calculating the instantaneous flow and cumulative flow of water pumped by the water pump. Users can grasp the start and stop of the water pump and understand the usage of water volume through the flow data

Water level gauge: Responsible for monitoring the water level value of the irrigation channel

Camera: It is used to collect image and video information around the pump room

AR7091F: Acquisition and control equipment, which collects, summarizes and processes the data from the above-mentioned sensors and reports it to the data platform. And receive remote instructions or local program logic to start/stop the water pump;

User data platform: Statistically process data from various sensors, monitor on-site operation conditions, conduct big data analysis, etc. Remote control of the start/stop of the water pump

Alotcer data Platform: Statistically process data from various sensors, monitor on-site operation conditions, remotely control the start/stop of water pumps, and remotely monitor/manage the operation status and configuration parameters of AR7091F

- Supports 5G/4G/3G/2G/ wired networks

- High-performance industrial 32-bit processor

- High-performance industrialcellular module

- Wide Operating Temperature(-40~+75ºC)

- Power range: DC 9~36V

- Support hardware and software WDT

- Support auto recovery mechanism, including online detect, auto redial when offline to make it always online

- Power port: reverse-voltage and over voltage protection

- Convenient configuration and maintenance interface

- WiFisupport 802.11b/g/n/ac. support AP, client

- WiFisupport 802.11ax (optional)

- Supports 2 serial ports (RS232/RS485)

- Supports 5 gigabit Ethernet ports

- Support2×DI, 2×DO

- The modular architectureof hardware and software

- Support Python secondary development platform (Python3)

- Support local log storage

- Support GPS positioning (optional)

- Support 2×PoE(optional)

- Support NB-IoT, LoRa, Ultrashort wave (optional)

- Supports various protocol conversions, such as: modbus to MQTT, modbusRTU to modbusTCP, etc. Customizable protocols are available

- Supports SMS sending and control functions