In the dynamic landscape of smart manufacturing, AGVs (Automated Guided Vehicles) have emerged as the linchpin for efficient material handling. Their role in streamlining production processes is pivotal, yet the industry is grappling with significant challenges that undermine the seamless operation of these vehicles. When AGVs experience unexpected downtimes, particularly in high – value automotive manufacturing workshops, the financial repercussions are staggering. For instance, a production line worth 8 million yuan can incur losses of up to 127,000 yuan per hour when an AGV halts (source: 2023 report from the Institute of Intelligent Manufacturing under the Ministry of Industry and Information Technology). This alarming scenario underscores the critical need for robust AGV communication solutions that can mitigate these losses and enhance operational efficiency.

Industry Pain Points

The challenges facing AGV communication in manufacturing environments are multifaceted and complex. Signal attenuation is a significant issue, especially in settings with metal shelves. AGVs navigating through such environments often experience signal loss rates as high as 37%. This frequent signal disruption leads to equipment shutdowns, causing costly delays and inefficiencies.

Another critical problem is handover delay. As AGVs move across different operational zones, the average instruction delay can reach 2.3 seconds. This seemingly short delay can have a profound impact on production efficiency, as it disrupts the smooth flow of operations and leads to bottlenecks in the production line.

Environmental interference further exacerbates these issues. Electromagnetic interference is a common occurrence in manufacturing settings, and its impact is substantial. On average, communication failures due to such interference can occur up to 3.6 times per month. These failures not only disrupt the normal functioning of AGVs but also pose significant risks to overall production stability.

Application of Alotcer’s 5G Industrial Router

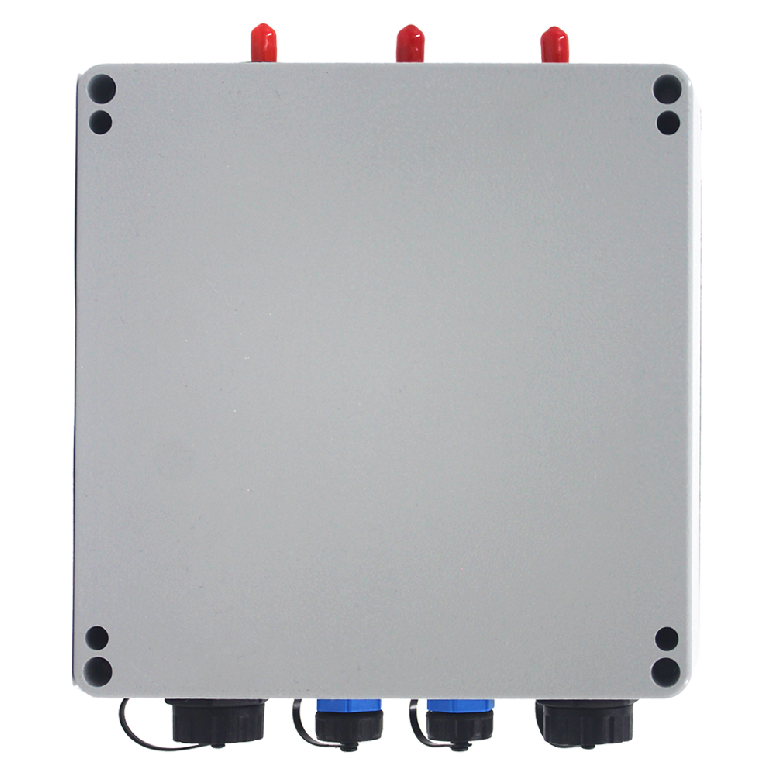

To address these pressing challenges, Alotcer has developed the AR7091G router, a cutting – edge solution that employs a triple – innovative design to ensure stable and efficient AGV communication. This router is specifically engineered to overcome the limitations of traditional communication systems and provide a reliable backbone for AGV operations.

One of the key features of the AR7091G router is its 5G dual – mode redundancy. This advanced capability supports parallel operation of NSA/SA dual – architecture, ensuring seamless signal switching. This means that AGVs can maintain constant connectivity, even when transitioning between different network environments. The router’s ability to switch between these architectures without interruption is a game – changer for industries where continuous operation is essential.

Another standout feature is the router’s smart band – switching capability. It automatically navigates between 2.4G and 5.8G bands to avoid obstacles and reduce interference. This intelligent switching mechanism significantly enhances the reliability of AGV communication by minimizing the impact of environmental factors that can disrupt signal integrity.

Application Advantages

The AR7091G router offers a host of application advantages that make it a superior choice for manufacturing environments. Its industrial – grade protection is a standout feature, with an IP67 protection rating that ensures durability and reliability. The router can operate in a wide temperature range of – 35℃ to 75℃, making it suitable for deployment in various harsh environments, from freezing cold storage areas to high – temperature manufacturing zones.

The router’s intelligent anti – interference capabilities are equally impressive. With dynamic spectrum management, it can improve interference avoidance efficiency by up to 80%. This means that AGVs can maintain stable communication even in environments with high levels of electromagnetic interference, reducing the risk of communication failures and associated production disruptions.

Dual – link backup is another critical feature of the AR7091G router. It supports parallel transmission of 5G and WiFi6, ensuring that the communication link is never interrupted. This redundancy is crucial for maintaining the continuity of AGV operations, as it provides a fail – safe mechanism that prevents communication outages.

The router’s ultra – low latency is a significant advantage for AGV operations. With end – to – end latency of less than 8ms, AGVs can respond more quickly to instructions, enhancing their overall efficiency and precision. This low latency is particularly important in high – precision manufacturing processes where timely response is critical.

Big data prediction is another advanced feature of the AR7091G router. It employs path optimization algorithms based on historical data to improve transportation efficiency. By analyzing past performance data, the router can optimize AGV routes in real – time, reducing travel time and improving overall operational efficiency.

Security is a paramount concern in modern manufacturing, and the AR7091G router does not disappoint. It is certified by the Electric Science Research Institute, ensuring that all data transmitted through the router is secure and protected from unauthorized access. This certification is a testament to the router’s robust security features, which are essential for safeguarding sensitive production data.

Industry Application

The effectiveness of the AR7091G router has been proven in real – world applications. A new energy vehicle battery factory that deployed this router experienced significant improvements in AGV performance. The most notable change was the dramatic reduction in AGV downtime. The factory saw a reduction from an average of 8.7 hours of downtime per month to just 1.2 hours. This improvement alone translates to substantial cost savings and increased production efficiency.

Instruction response speed also saw a significant boost. The factory reported a 3.8 – fold increase in response speed, which means that AGVs could execute instructions more quickly and efficiently. This improvement had a cascading effect on the entire production line, leading to smoother operations and reduced bottlenecks.

Network maintenance costs were also significantly reduced. The factory experienced a 72% reduction in maintenance costs, which can be attributed to the router’s robust design and advanced features. The reduced downtime and improved reliability of the AGV system meant that fewer resources were needed for maintenance and troubleshooting.

Space utilization within the factory also improved by 19%. This increase can be attributed to the more efficient operation of AGVs, which allowed for better – optimized workflows and reduced congestion in high – traffic areas.

The technical supervisor of the factory highlighted the most significant change: the improvement in the collaborative efficiency of the AGV fleet. In high – density storage areas, the material sorting accuracy rate reached an impressive 99.98%. This level of precision is crucial in manufacturing environments where accuracy can make the difference between a successful production run and costly errors.

Selection Guide

Choosing the right 5G industrial router is a critical decision for any manufacturing enterprise. When selecting a router, several key factors should be considered to ensure that the chosen solution meets the specific needs of the operation.

Electromagnetic environment level is a crucial consideration. It is essential to confirm the electromagnetic environment of the factory area and select a router model that is suitable for the specific conditions. This step ensures that the router can operate effectively without being adversely affected by the surrounding electromagnetic fields.

AGV peak concurrent quantity is another important factor. It is necessary to evaluate the peak concurrent quantity of AGVs to ensure that the router can meet the demand. A router that cannot handle the peak load will result in communication delays and potential disruptions to AGV operations.

Device installation space should also be carefully assessed. It is important to check the space limitations for device installation to ensure that the router can be installed smoothly. Insufficient space can lead to installation difficulties and may require additional modifications to the factory layout.

Network architecture compatibility is vital. It is essential to verify the compatibility of the existing network architecture with the router. Incompatibilities can lead to communication issues and may require significant modifications to the existing infrastructure.

Anti – vibration performance is another key consideration. It is important to test the router’s anti – vibration performance to ensure stable operation in harsh environments. Factories with high – vibration machinery or equipment need a router that can withstand these conditions without compromising performance.

Frequently Asked Questions

| Does upgrading from traditional solutions require modifying AGVs? |

|---|

| The AR7091G router features a plug – and – play design that allows existing AGV devices to connect without modification. This design ensures a seamless transition to the new communication system without the need for costly and time – consuming modifications to the AGVs themselves. |

| How does the router handle signal interference in a busy manufacturing environment? |

|---|

| CThe router employs dynamic spectrum management to intelligently switch between 2.4G and 5.8G bands. This feature significantly reduces the impact of signal interference, ensuring stable and reliable communication for AGVs even in environments with high – density electromagnetic activity. |

| What kind of security measures does the router have to protect data? |

|---|

| The AR7091G router is certified by the Electric Science Research Institute, ensuring that all data transmitted through it is secure. It employs advanced encryption protocols to protect data from unauthorized access, providing a robust security framework for manufacturing operations. |

| Can the router support multiple AGVs simultaneously? |

|---|

| Yes, the router is designed to handle multiple AGVs concurrently. Its advanced features, such as dual – link backup and low latency, ensure that multiple AGVs can operate efficiently without communication delays or disruptions. |

| How does the router contribute to overall production efficiency? |

|---|

| The router’s ultra – low latency and big data prediction capabilities enhance AGV response speed and optimize transportation routes. These features translate to faster material handling, reduced downtime, and improved overall production efficiency. The router’s reliability also reduces maintenance costs and ensures continuous operation, contributing to a more efficient production environment. |