I. Understanding PLC: The Backbone of Industrial Automation

A. The Basics of PLC: A Brief Overview of Programmable Logic Controllers

PLCs are the core of industrial automation, designed to automate processes like manufacturing, assembly lines, and energy management. They receive inputs from sensors, process the data, and trigger outputs to control machinery. PLCs are reliable, robust, and essential for ensuring efficient, consistent operations in industrial settings. Their ability to operate in harsh environments, coupled with real-time processing capabilities, makes them indispensable in modern industry.

B. PLC Communication Challenges: The Need for Reliable and Secure Remote Connectivity

Despite their reliability, PLCs face significant communication challenges, particularly as industries become more interconnected. Traditional PLC networks were designed for local control, but modern industrial environments demand remote access and control, introducing new vulnerabilities. Ensuring secure, reliable communication between PLCs and remote systems is critical to prevent downtime and protect against cyber threats. This is where VPN routers come into play, providing the secure, encrypted connectivity needed for efficient remote PLC management.

II. Introducing VPN Routers: The Guardians of PLC Networks

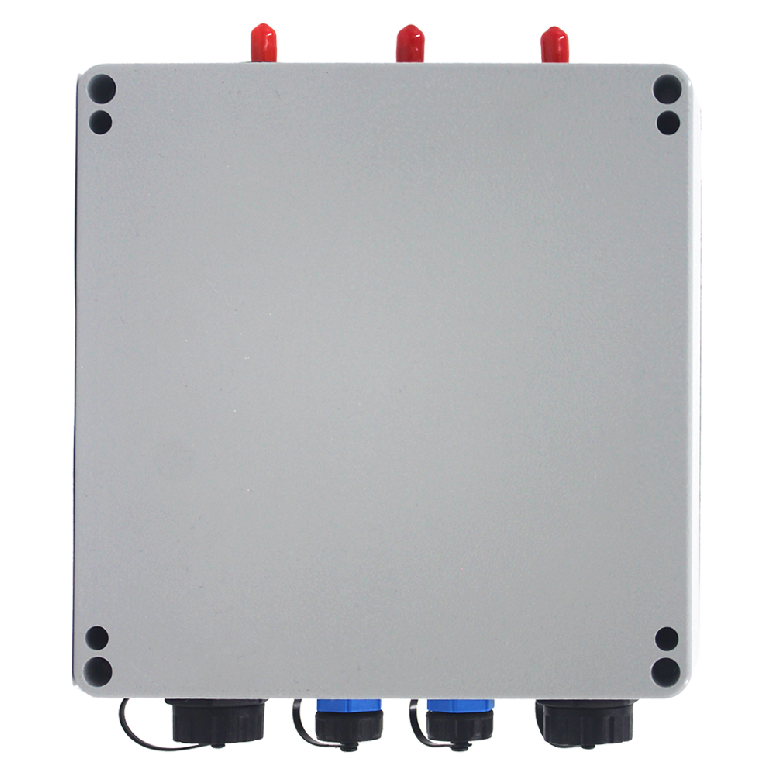

A. What is a VPN Router? A Breakdown of Its Core Functions

A VPN router creates a secure, encrypted tunnel for data transmission between devices across the internet, ensuring privacy and protection from unauthorized access. It connects remote devices to a central network, allowing users to securely access resources as if they were on-site. This is particularly crucial in industrial environments, where secure remote access to PLCs and other critical systems is needed for efficient operations.

B. How VPN Routers Enhance PLC Connectivity: Building a Secure Tunnel for Data Transmission

VPN routers enhance PLC connectivity by encrypting data as it travels between remote locations and the central network, protecting against cyber threats. They also allow for secure remote monitoring and control of PLCs, which minimizes downtime and increases operational efficiency. By creating a secure, reliable network, VPN routers ensure that PLC systems can operate seamlessly, even when accessed remotely.

III. Boosting PLC Efficiency with VPN Routers: Key Benefits

A. Enhanced Security: Protecting Sensitive PLC Data from Cyber Threats

VPN routers provide encrypted tunnels for PLC data, shielding it from cyber threats. This level of security is crucial in industrial environments, where any breach could disrupt operations. By encrypting data traffic and using robust authentication methods, VPN routers help prevent unauthorized access and protect sensitive information, ensuring the integrity of industrial processes.

B. Remote Monitoring and Control: Real-Time Access to PLC Systems from Anywhere

VPN routers enable remote access to PLCs, allowing engineers to monitor and control systems from anywhere. This reduces the need for on-site visits, cuts down on response times, and ensures continuous operations. With real-time access, engineers can quickly address issues, perform maintenance, and optimize processes without being physically present, enhancing overall efficiency.

C. Improved Network Performance: Optimizing Data Transfer for Faster Response Times

VPN routers prioritize PLC traffic, ensuring that critical data is transmitted quickly and efficiently. By optimizing network performance, they reduce latency and prevent bottlenecks, which is vital for maintaining the responsiveness of PLC systems. This results in smoother operations and minimizes the risk of delays in critical industrial processes.

D. Cost Reduction: Lowering IT Infrastructure Expenses with VPN Routers

Implementing VPN routers can lead to significant cost savings by reducing the need for extensive physical infrastructure. They allow for centralized management and remote access, cutting down on travel costs and minimizing the need for on-site maintenance. Additionally, the enhanced efficiency and reduced downtime provided by VPN routers contribute to lower operational expenses.

IV. Choosing the Right VPN Router for Your PLC Network

A. VPN Protocols: Understanding the Differences Between PPTP, L2TP, and IPsec

Selecting the right VPN protocol is crucial for ensuring secure and efficient PLC network connectivity. PPTP is the simplest but offers weaker security, suitable for less critical applications. L2TP provides stronger security by combining with IPsec, offering a balance between performance and security. IPsec is the most secure, ideal for protecting sensitive industrial data, but can be more complex to configure and may slightly impact performance.

B. Hardware Specifications: Processor Speed, Memory, and Network Interface Considerations

Hardware specifications directly impact the router’s ability to manage data traffic and maintain secure connections. A faster processor ensures quick data encryption and decryption, essential for real-time applications. Sufficient memory is needed to handle multiple connections simultaneously, especially in large networks. Consider network interfaces that support high-speed Ethernet and possibly cellular connectivity for backup, ensuring reliable and uninterrupted operations.

C. Security Features: Essential Features for Protecting Your PLC Network

Security features are paramount in a VPN router. Look for firewalls to block unauthorized access, AES-256 encryption for robust data protection, and multi-factor authentication (MFA) to add an extra layer of security. Additionally, features like intrusion detection systems (IDS) and regular firmware updates help protect the network against emerging threats and vulnerabilities.

V. Configuring Your VPN Router for Optimal PLC Performance

A. Basic Setup: Connecting the VPN Router to Your PLC Network

Begin by connecting the VPN router to your PLC network. Use Ethernet cables to link the router to both your PLCs and network switch. Access the router’s web interface and configure the basic network settings, including IP addresses and subnet masks, to ensure smooth communication between devices.

B. VPN Configuration: Establishing a Secure Connection Between Remote Locations

Set up the VPN connection by selecting the appropriate VPN protocol (e.g., OpenVPN, IPsec) and entering server details. Configure authentication methods and encryption settings to secure the data transmitted between remote locations and your PLC network. Test the connection to verify that it is functioning correctly and securely.

C. Network Optimization: Fine-Tuning Settings for Maximum Efficiency

Optimize network performance by adjusting settings such as Quality of Service (QoS) to prioritize PLC traffic, ensuring critical data is transmitted efficiently. Monitor network usage and adjust bandwidth allocation to prevent bottlenecks. Regularly update router firmware and review settings to maintain optimal performance and security.

VI. Overcoming Common Challenges: Troubleshooting VPN Router Issues

A. Connectivity Problems: Diagnosing and Resolving Network Connectivity Issues

Connectivity issues often stem from incorrect configurations or network conflicts. Start by checking physical connections and ensuring cables are properly connected. Verify that VPN settings are correct and that the router’s firmware is up-to-date. Use diagnostic tools to identify network conflicts or IP address issues, and consult logs for error messages to pinpoint the problem.

B. VPN Connection Drops: Identifying and Addressing Disconnection Causes

Frequent VPN disconnections can be caused by unstable internet connections, outdated firmware, or incorrect VPN settings. Ensure that your internet connection is stable and check for firmware updates. Review VPN configuration settings and adjust as needed to maintain a stable connection. If disconnections persist, examine the router’s logs for patterns and consider adjusting VPN protocols or server settings.

C. Performance Bottlenecks: Optimizing Network Traffic for Smooth PLC Operation

Performance issues often arise from inadequate bandwidth allocation or network congestion. Analyze network traffic to identify bottlenecks and adjust QoS settings to prioritize PLC data. Ensure the VPN router is equipped to handle the network load and consider upgrading hardware if necessary. Regularly monitor network performance and make adjustments to maintain optimal operation.

VII. Applications: How VPN Routers Revolutionize Industrial Automation

A. Case Study 1: Enhancing Remote Monitoring in a Manufacturing Plant

A large manufacturing plant struggled with remote PLC monitoring, leading to frequent downtime and high travel costs for on-site troubleshooting. By implementing VPN routers, the plant established secure connections, enabling engineers to monitor and adjust PLCs in real-time from the control room. This reduced downtime, travel expenses, and enhanced network security by encrypting data between central and remote sites.

B. Case Study 2: Streamlining Operations in a Multi-Site Industrial Facility

A multi-site industrial facility needed a solution to manage its PLC network across various locations. Manual data collection was slow and error-prone. VPN routers unified the network, allowing real-time data transmission to a central database. Engineers could troubleshoot PLCs remotely, streamlining operations and reducing the need for on-site visits. The routers also prioritized PLC traffic, ensuring critical commands were executed promptly, reducing production delays.

C. Case Study 3: Securing a Water Treatment Plant’s SCADA System

A water treatment plant required secure, reliable communication between its PLCs and SCADA system. VPN routers with AES-256 encryption and multi-factor authentication provided secure data transmission, protecting the network from cyber threats. Operators could monitor and control PLCs remotely, enabling quicker response times and ensuring uninterrupted water treatment operations.

VIII. Future Trends: The Evolving Role of VPN Routers in Industrial Automation

A. Integration with IoT: How VPN Routers are Adapting to the Internet of Things

As IoT transforms industrial automation, VPN routers are evolving to support connected devices. They handle increased data traffic from IoT sensors and actuators, ensuring secure, efficient transmission. VPN routers are now equipped with IoT-specific protocols, like MQTT and CoAP, facilitating communication between IoT devices and PLCs, which is crucial for the success of future automation projects.

B. Advances in VPN Technology: What’s Next for Secure Industrial Networks

VPN technology is advancing with new developments aimed at enhancing security and performance. Quantum-resistant encryption algorithms are being developed to protect against future quantum computing threats. Software-defined networking (SDN) is being combined with VPNs for greater network flexibility and control. The rise of 5G technology will also impact VPN routers, offering faster speeds, lower latency, and better support for real-time industrial applications.

IX. Conclusion: Unlocking the Full Potential of PLCs with VPN Routers

VPN routers are crucial for modern industrial automation, providing secure, reliable connectivity that enhances PLC network performance. They enable remote monitoring, improve security, and optimize network operations, reducing costs and protecting critical infrastructure. As technology evolves, VPN routers will continue to play a vital role in industrial automation, adapting to new challenges like IoT integration and advancing encryption methods.

FAQs

Q1: What is the primary purpose of a VPN router in industrial automation?

A VPN router in industrial automation primarily serves to establish a secure and encrypted connection between remote locations and a central PLC network. This enables secure remote monitoring, control, and data transmission, protecting sensitive industrial processes from cyber threats.

Q2: How does a VPN router enhance the security of a PLC network?

A VPN router enhances the security of a PLC network by encrypting all data transmitted between connected devices, preventing unauthorized access. It also provides features like firewalls, multi-factor authentication, and intrusion detection systems to safeguard the network from cyber threats.

Q3: Can VPN routers support real-time communication in industrial applications?

Yes, VPN routers can support real-time communication by prioritizing PLC traffic and ensuring low-latency data transmission. Features like Quality of Service (QoS) and load balancing help optimize network performance, making VPN routers suitable for real-time industrial applications.

Q4: What are the key factors to consider when choosing a VPN router for a PLC network?

Key factors to consider include the VPN protocol used, hardware specifications (such as processor speed and memory), security features (like encryption and firewall protection), and network interfaces. These factors determine the router’s ability to handle the demands of an industrial PLC network.

Q5: How do VPN routers integrate with IoT devices in industrial settings?

VPN routers integrate with IoT devices by supporting IoT-specific protocols and handling the increased data traffic generated by these devices. This integration ensures that IoT data is transmitted securely and efficiently within the PLC network, enabling advanced industrial automation.