Network communication interfaces are the pathways through which industrial routers interact with the outside world and the cornerstone of device interconnectivity. They are primarily divided into two categories: wired and wireless.

Wired Communication Interfaces

The RJ45 Ethernet interface is the most prevalent, encompassing both LAN (Local Area Network) and WAN (Wide Area Network) interfaces. LAN interfaces, typically configured with four or more ports, are used to build internal LANs. They tightly connect various devices on the workshop floor and production lines, enabling efficient data transmission and sharing. WAN interfaces, on the other hand, serve as the bridge to external networks, such as the Internet or corporate intranets, ensuring remote data transmission and interaction. Additionally, the SFP fiber – optic interface, with its high – speed transmission and long – distance communication capabilities, has become the preferred choice for long – distance interconnection in industrial environments. Particularly in harsh environments or scenarios requiring long – distance communication, the advantages of fiber – optic interfaces are especially prominent.

Wireless Communication Interfaces

These mainly include WiFi and cellular network interfaces (such as 3G/4G/5G). WiFi interfaces enable industrial routers to create wireless network coverage, offering flexible connection solutions for areas where cabling is difficult. By setting up an SSID and password, network security can be effectively ensured, preventing unauthorized access. Cellular network interfaces, on the other hand, achieve network access through SIM cards, without relying on fixed network infrastructure. This provides great convenience for temporary network deployment or network coverage in remote areas.

Serial Communication Interfaces

Serial communication interfaces hold a significant position in industrial control systems and are the key link connecting serial devices and control systems. Industrial routers are typically equipped with three types of serial communication interfaces: RS232, RS485, and RS422.

The RS232 interface is suitable for short – distance communication and is the preferred choice for point – to – point serial device connections, such as printers and scanners. Despite its limited communication distance (usually not exceeding 15 meters), it is still widely used in many small – scale industrial control systems. The RS485 interface, with its long – distance communication capability (up to 1200 meters) and multi – point connection ability, has become the top choice for large – scale industrial sites. It allows multiple devices to communicate through a single cable, greatly simplifying cabling complexity. The RS422 interface, an upgraded version of RS485, not only retains the advantage of long – distance communication but also increases the data transmission rate, making it suitable for a broader range of industrial control applications.

Audio and Video Transmission Interfaces

Although audio and video transmission interfaces are not common in industrial routers, they play an irreplaceable role in certain specific industries. The HDMI interface, with its high – definition video and multi – channel audio transmission capabilities, has become the preferred choice for remote video surveillance and conferencing systems. The DisplayPort interface, with its high compatibility and powerful digital audio and video transmission capabilities, provides a stable connection for industrial display devices. The 3.5mm audio interface is suitable for simple audio input and output, such as on – site sound acquisition and playback.

Bus Connection Interfaces

Bus connection interfaces allow industrial routers to connect to external devices that support various bus protocols, greatly expanding their application range. The USB interface, with its universality and flexibility, has become the preferred choice for expanding various functional modules, such as mounting 4G modules and storage devices. The CAN bus interface is widely used in automotive electronic networks and industrial control systems, enabling device interconnection within vehicles and on production lines. The Modbus interface, a widely used serial communication protocol in the industrial field, provides a standard interface for serial connections of industrial devices. The Profibus interface, with its open fieldbus standard, has been widely used in the industrial manufacturing and process control industries.

Data Storage Interfaces

Data storage interfaces provide industrial routers with the ability to expand external storage, ensuring the persistent storage and efficient management of important data. The SD card slot, with its compact and portable features, has become an ideal choice for storing logs and configuration files. The mSATA interface and SATA interface provide high – capacity and stable storage solutions, suitable for applications requiring long – term storage of large – volume data, such as high – definition video surveillance records.

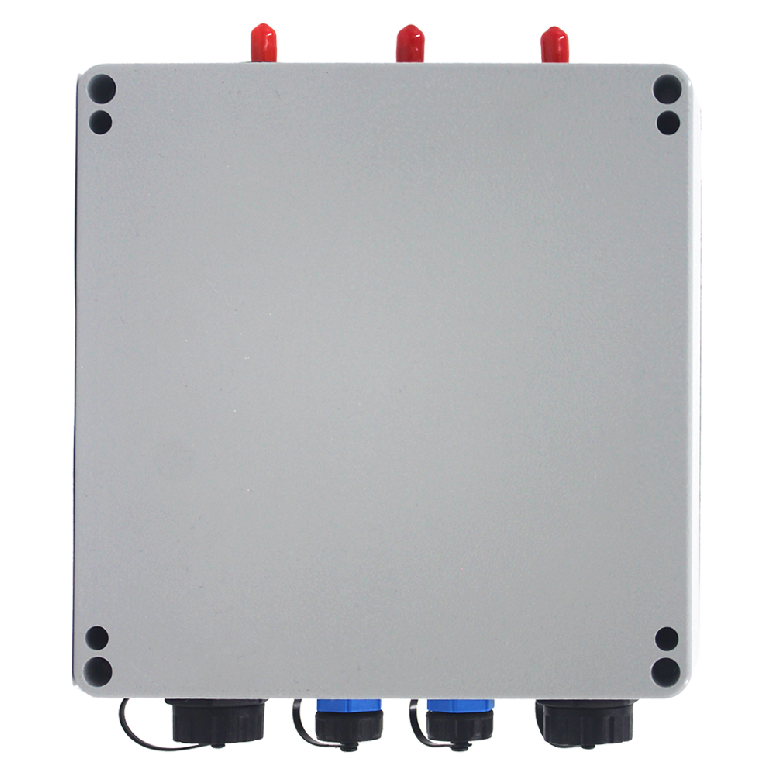

Other Auxiliary Interfaces

In addition to the aforementioned main interfaces, industrial routers are also equipped with a variety of other interfaces to meet the diverse needs of different industrial scenarios. The DIO interface provides a general – purpose digital input/output interface for connecting sensors and actuators. The AIO interface is used for acquiring analog signals, such as environmental parameters like temperature and humidity. The relay interface can drive high – power loads, such as motors and lights. The M – Bus interface is used to connect metering devices for heat, water, and gas, enabling intelligent energy – consumption monitoring. The PoE interface supplies power to connected devices, simplifying cabling complexity. The DC terminal serves as a high – power supply interface, ensuring the stable operation of the industrial router. The SMA antenna interface is used to connect external LTE antennas to improve signal reception quality. Buttons and indicator lights provide a simple and intuitive human – machine interface for basic operations and status monitoring. The Console port is used for command – line debugging access, providing technicians with a powerful debugging tool.