[ez-toc]

The Achilles’ Heel of Industry: The Peril of Downtime

A. The High Cost of Network Outages: Counting the Losses in Dollars and Productivity

Downtime in industrial settings isn’t just an inconvenience—it’s a full-blown disaster. When your network goes down, production grinds to a halt, and the financial repercussions can be staggering. Let’s break down why uptime is so critical and the real cost of network outages.

Consider a manufacturing plant. Every minute that the production line is idle due to a network outage translates to lost revenue. Machines stand still, workers wait around, and deadlines slip. Imagine a factory that produces 100 units of product per hour, each worth $50. A one-hour network outage means $5,000 in lost production. Extrapolate that to a full day or multiple instances in a month, and you’re staring at a financial black hole.

Beyond direct revenue loss, downtime also incurs costs in terms of labor. Workers who can’t perform their tasks still need to be paid. Moreover, the pressure to make up for lost time often leads to overtime pay and increased labor costs. For industries operating with tight margins, these additional expenses can be a severe blow.

Then there’s the ripple effect on supply chains. In sectors like oil and gas, network outages can disrupt the monitoring and control systems of remote infrastructure, leading to operational inefficiencies. Delayed shipments and inventory mismanagement compound the problem, causing a domino effect that impacts partners and customers down the line. For example, if a pipeline monitoring system goes offline, it might delay the detection of issues, leading to costly repairs and environmental damage.

Examples illustrate these points starkly. In 2017, a major automotive manufacturer experienced a network outage that halted production across multiple plants. The downtime lasted only a few hours but resulted in millions of dollars in lost revenue and delayed shipments. Similarly, in the oil and gas industry, a network failure at an offshore drilling site can lead to unmonitored operations, posing safety risks and financial losses due to potential accidents or regulatory fines.

The consequences of downtime extend beyond immediate financial losses. There’s the damage to reputation and customer trust. Frequent network outages signal unreliability, causing customers to reconsider their relationships with affected businesses. In today’s interconnected world, where word spreads fast, maintaining uptime is critical to preserving brand integrity and customer loyalty.

Given these stakes, it’s no wonder that businesses are investing heavily in solutions to prevent downtime. Enter the world of industrial failover and cellular routers, designed to keep the wheels of industry turning smoothly, even when primary networks falter. These technologies are not just a nice-to-have but a necessity in the modern industrial landscape, where uptime is synonymous with survival and success.

B. Examples: How Downtime Impacts Different Industries

Downtime’s impact isn’t uniform—it varies dramatically across industries. Let’s explore specific examples from manufacturing and oil & gas to understand the unique challenges and repercussions.

Manufacturing: In manufacturing, network downtime means production halts. Assembly lines stop, machinery idles, and workers wait. A major electronics manufacturer experienced a network failure that stopped their production line for half a day. This incident not only caused significant revenue loss but also disrupted the supply chain, delaying shipments to retailers and customers. The downtime led to a backlog that took weeks to clear, highlighting the critical importance of network reliability in maintaining smooth operations.

Oil & Gas: The oil and gas industry faces unique challenges due to its reliance on remote monitoring and control systems. A network outage in this sector can halt the flow of critical data from pipelines and drilling sites. For instance, a network failure at a remote oilfield can prevent real-time monitoring, leading to undetected issues and potential safety hazards. This lack of visibility can cause operational inefficiencies and increased risks, demonstrating the vital need for robust network solutions that ensure continuous connectivity.

Remote Infrastructure: For industries that rely on remote infrastructure, such as telecommunications or utilities, network outages can disrupt essential services. A power utility company, for example, experienced a network failure that interrupted their remote monitoring systems. This disruption led to delayed responses to outages, affecting thousands of customers and causing significant reputational damage. The incident underscored the necessity of reliable network solutions that can withstand the challenges of remote environments.

These examples illustrate the profound impact of network downtime across various industries. Each case highlights the need for robust and reliable network solutions to ensure continuous operations, protect revenue streams, and maintain customer trust.

Building Network Resilience: Introducing Redundancy Solutions

Network redundancy is the foundation of building a resilient industrial network. By ensuring that there’s always a backup, businesses can avoid the pitfalls of downtime. Let’s delve into what redundancy means and explore different approaches.

A. The Concept of Redundancy: Why Two is Always Better Than One

Redundancy, in the simplest terms, means having a backup ready to take over when the primary system fails. It’s like having a spare tire in your car—you hope never to use it, but when you need it, it can save the day. In network terms, redundancy involves having secondary pathways or systems that kick in automatically if the primary ones fail.

For industrial networks, redundancy is crucial. These networks are the lifelines of production and operations. Without redundancy, a single point of failure can bring everything to a halt. Implementing redundancy ensures continuous operations, even when unforeseen issues arise.

Imagine a factory that relies on a single internet connection. If that connection goes down, so does the entire production line. However, with a redundant setup—such as a secondary internet connection or a cellular failover—the factory can switch to the backup connection instantly, maintaining operations without missing a beat.

B. Types of Network Redundancy: Exploring Different Approaches

There are various approaches to achieving network redundancy, each suited to different needs and environments. Two primary methods are failover and load balancing.

Failover: Failover redundancy is about having a backup that takes over automatically when the primary system fails. For example, an industrial failover router might use a primary wired connection but switch to a cellular network if the wired connection fails. This switch is seamless, ensuring that network connectivity is maintained without interruption. Failover is crucial for mission-critical applications where any downtime is unacceptable.

Load Balancing: Load balancing, on the other hand, distributes network traffic across multiple connections to optimize performance and reliability. Instead of relying on a single connection, load balancing uses multiple pathways simultaneously. This approach not only provides redundancy but also enhances network efficiency. For instance, an industrial router might use two internet connections, balancing traffic between them to prevent any single connection from becoming overloaded. If one connection fails, the router seamlessly shifts all traffic to the remaining active connections.

Both failover and load balancing offer unique advantages. Failover ensures a backup is always available, while load balancing enhances overall network performance and reliability. The choice between the two depends on the specific needs and priorities of the industrial environment.

To implement these solutions effectively, businesses need to assess their network requirements, considering factors like bandwidth needs, critical applications, and potential points of failure. By understanding these aspects, they can choose the right redundancy solution to safeguard their operations.

In conclusion, building network resilience through redundancy is not just a best practice—it’s a necessity for modern industrial operations. Whether through failover or load balancing, redundancy ensures continuous connectivity, protecting businesses from the costly consequences of downtime.

In the Ring: Industrial Failover Routers vs. Cellular Routers

When it comes to ensuring uptime, industrial failover routers and cellular routers are two heavyweight contenders. Both offer unique benefits and capabilities, making them essential tools in the fight against network downtime. Let’s examine each type in detail.

A. Industrial Failover Routers: The Stalwart Champions

Built for Tough Environments: Durability and Reliability You Can Trust

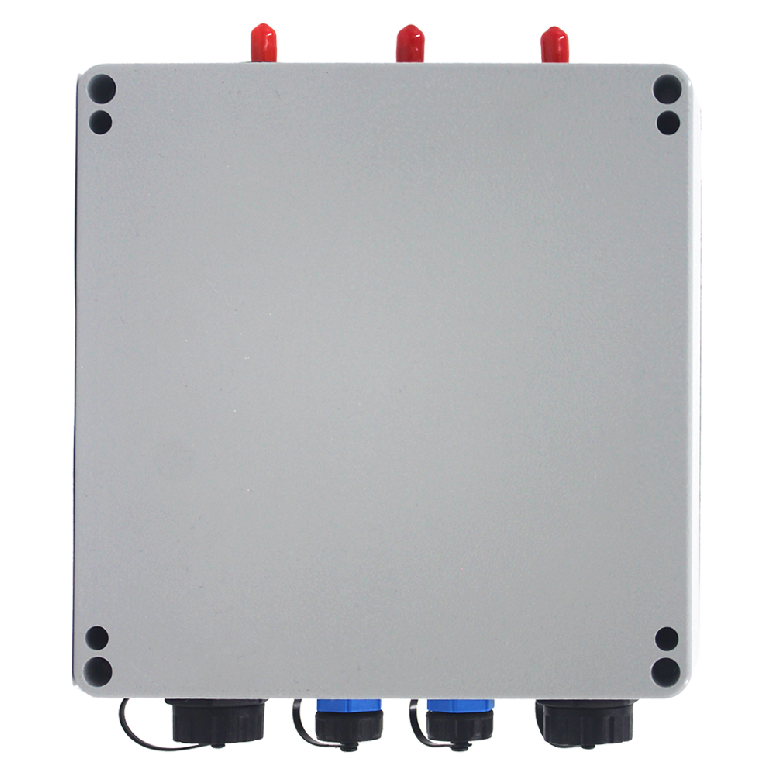

Industrial failover routers are designed to withstand the harshest conditions. These rugged devices are built to operate in extreme temperatures, resist dust and moisture, and endure physical shocks. This durability ensures that they can maintain network connectivity in environments where standard routers would fail.

For example, consider a manufacturing plant with high levels of dust and vibrations. An industrial failover router in this setting must continue to function reliably, ensuring uninterrupted communication between machines and control systems. These routers are often encased in sturdy, industrial-grade housings that protect them from environmental hazards, ensuring they can withstand the rigors of demanding industrial environments.

Wired Backup Connections: Leveraging Existing Infrastructure for Seamless Failover

One of the primary advantages of industrial failover routers is their ability to use wired backup connections. These routers typically support multiple WAN (Wide Area Network) connections, allowing them to switch seamlessly between primary and backup internet sources. This capability ensures continuous network connectivity, even if the primary connection fails.

For instance, an industrial facility might have its primary connection via fiber optic and a secondary connection via DSL. If the fiber optic connection goes down, the failover router automatically switches to the DSL connection, ensuring that critical operations continue without interruption. This seamless transition is vital for maintaining productivity and avoiding costly downtime.

Advanced Features: Dual SIM Support, Load Balancing Capabilities

Modern industrial failover routers come equipped with advanced features that enhance their functionality and reliability. Dual SIM support, for example, allows these routers to use two cellular networks simultaneously. This capability provides an additional layer of redundancy, ensuring that connectivity is maintained even if one cellular network experiences issues.

Load balancing is another valuable feature. By distributing network traffic across multiple connections, industrial failover routers can optimize performance and prevent any single connection from becoming overloaded. This approach enhances network efficiency and reliability, ensuring that critical applications receive the bandwidth they need.

Overall, industrial failover routers are the stalwart champions of network redundancy, offering durability, reliability, and advanced features that ensure continuous connectivity in the most demanding environments.

The Cellular Contender: Advantages of Cellular Routers

While industrial failover routers are formidable, cellular routers bring their unique advantages to the table. These devices offer untethered connectivity and rapid deployment, making them ideal for various applications.

A. Always-On Connectivity: Untethered Backup with Cellular Networks

Cellular routers provide always-on connectivity by leveraging cellular networks. Unlike wired connections, which can be susceptible to physical disruptions, cellular networks offer a wireless alternative that is less prone to outages. This untethered connectivity ensures that network operations continue smoothly, even if the primary wired connection fails.

For example, a remote construction site might rely on a cellular router for internet connectivity. In such environments, where laying traditional wired infrastructure is impractical, cellular routers provide a reliable and flexible solution. By connecting to multiple cellular networks, these routers ensure continuous connectivity, enabling real-time communication and monitoring.

B. Rapid Deployment: Quick and Easy Set Up for Remote Locations

One of the standout advantages of cellular routers is their rapid deployment capability. Setting up a cellular router is quick and straightforward, making it an ideal choice for remote locations or temporary setups. This ease of deployment is particularly valuable in industries that require immediate network connectivity without the delays associated with laying wired infrastructure.

Consider a disaster recovery scenario. In the aftermath of a natural disaster, restoring network connectivity quickly is crucial for coordinating relief efforts. Cellular routers can be deployed rapidly in such situations, providing instant connectivity and enabling communication between response teams. This quick setup capability is also beneficial for temporary work sites, such as film shoots or construction projects, where reliable connectivity is needed for a limited period.

C. Scalability: Adapting to Changing Network Needs (Data Usage, Coverage)

Cellular routers offer exceptional scalability, allowing businesses to adapt their network infrastructure to changing needs. Whether it’s increasing data usage or expanding coverage to new areas, cellular routers can scale seamlessly to meet these demands.

For instance, an agricultural operation might initially use cellular routers to monitor a small number of sensors in a specific field. As the operation expands and more sensors are added across multiple fields, the cellular routers can scale to accommodate the increased data traffic. This scalability ensures that the network infrastructure grows in tandem with the business, providing continuous and reliable connectivity.

In conclusion, cellular routers are the agile contenders in the realm of network redundancy. Their always-on connectivity, rapid deployment, and scalability make them a versatile and powerful solution for various applications, particularly in remote and dynamic environments.

Choosing Your Champion: Factors to Consider When Selecting a Redundancy Solution

Selecting the right redundancy solution involves careful consideration of various factors. By assessing network needs, deployment environments, and cost considerations, businesses can make informed decisions that ensure continuous connectivity and optimal performance.

A. Network Needs Assessment: Identifying Bandwidth Requirements and Critical Applications

The first step in choosing a redundancy solution is conducting a thorough network needs assessment. This involves identifying bandwidth requirements and critical applications that need uninterrupted connectivity.

For example, a manufacturing plant with automated machinery and real-time monitoring systems will have high bandwidth needs and require a robust redundancy solution to ensure continuous operations. On the other hand, a small remote office may have lower bandwidth requirements but still need reliable connectivity for critical communications.

By understanding the specific network needs, businesses can select a redundancy solution that meets these requirements. This assessment should consider current needs and future growth, ensuring the chosen solution can scale to accommodate increasing demands.

B. Deployment Environment: Considering Physical Location and Infrastructure Availability

The deployment environment plays a crucial role in selecting the right redundancy solution. Factors such as physical location, infrastructure availability, and environmental conditions must be considered.

For instance, an industrial facility located in a remote area with limited wired infrastructure may benefit more from a cellular router’s rapid deployment and untethered connectivity. In contrast, an urban facility with robust wired infrastructure might prefer an industrial failover router with dual WAN support.

Environmental conditions, such as temperature extremes, dust, and moisture, should also be considered. Industrial failover routers are designed to withstand harsh conditions, making them suitable for challenging environments. Understanding these factors ensures the chosen solution can operate reliably in the specific deployment environment.

C. Cost Considerations: Balancing Upfront Investment with Long-Term Benefits

Cost is a significant consideration when selecting a redundancy solution. Businesses must balance the upfront investment with the long-term benefits to make an informed decision.

Industrial failover routers typically involve higher upfront costs due to their advanced features and durability. However, their ability to prevent costly downtime and ensure continuous operations can provide substantial long-term benefits, offsetting the initial investment.

Cellular routers, on the other hand, offer a cost-effective solution for rapid deployment and scalability. Their lower upfront costs and flexibility make them an attractive option for businesses looking to minimize initial expenses while maintaining reliable connectivity.

In conclusion, choosing the right redundancy solution requires a comprehensive assessment of network needs, deployment environments, and cost considerations. By carefully evaluating these factors, businesses can select a solution that ensures continuous connectivity, protects against downtime, and supports their long-term goals.

Beyond the Basics: Advanced Features to Look For

When selecting a redundancy solution, it’s essential to look beyond the basics and consider advanced features that enhance functionality and reliability. These features ensure seamless transitions during outages, secure communication channels, and efficient network management.

A. Automatic Failover: Ensuring Seamless Transition During Outages

Automatic failover is a critical feature for any redundancy solution. This capability ensures that the backup connection takes over immediately when the primary connection fails, maintaining continuous connectivity without manual intervention.

For example, an industrial failover router with automatic failover can switch from a primary wired connection to a cellular backup within seconds of detecting an outage. This seamless transition is vital for mission-critical applications where even a few minutes of downtime can have significant consequences.

Automatic failover also provides peace of mind, knowing that the network will remain operational regardless of unforeseen issues with the primary connection. This feature is particularly important in industries where continuous operations are essential, such as manufacturing, healthcare, and finance.

B. VPN Tunneling: Securing Communication Channels for Sensitive Data

VPN tunneling is another essential feature, providing secure communication channels for transmitting sensitive data. This capability is crucial for protecting data integrity and ensuring privacy in industrial environments.

For instance, a manufacturing plant that transmits sensitive production data to a remote control center can use VPN tunneling to secure this communication. By encrypting the data, VPN tunneling prevents unauthorized access and ensures that the information remains confidential.

In addition to security, VPN tunneling also enhances network reliability. By creating a dedicated and secure connection, VPN tunneling ensures that critical data reaches its destination without interference or delays.

C. Remote Management: Monitoring and Controlling Your Network from Anywhere

Remote management capabilities are invaluable for maintaining and troubleshooting network infrastructure. This feature allows administrators to monitor and control the network from any location, providing real-time visibility and control.

For example, an industrial facility with multiple remote sites can use remote management to monitor network performance, identify issues, and implement solutions without needing on-site presence. This capability reduces downtime, minimizes maintenance costs, and ensures that the network operates efficiently.

Remote management also provides valuable insights into network performance, helping businesses optimize their infrastructure and address potential issues before they become critical. By enabling proactive network management, this feature enhances overall reliability and efficiency.

In conclusion, advanced features like automatic failover, VPN tunneling, and remote management are essential for maximizing the functionality and reliability of redundancy solutions. These capabilities ensure seamless transitions during outages, secure communication channels, and efficient network management, providing businesses with the tools they need to maintain continuous connectivity and protect their operations.

Case Studies: Examples of Successful Redundancy Implementations

Real-world case studies provide valuable insights into the effectiveness of redundancy solutions in various industrial settings. These examples demonstrate how businesses can implement these solutions to ensure continuous connectivity and protect their operations.

A. Securing a Manufacturing Plant: Ensuring Uptime for Production Lines

A leading electronics manufacturer faced frequent network outages that disrupted their production lines, causing significant revenue loss and operational inefficiencies. To address this issue, the company implemented an industrial failover router with dual WAN support.

By leveraging both a primary wired connection and a cellular backup, the failover router ensured continuous connectivity. The automatic failover capability allowed seamless transitions between connections, preventing production halts and maintaining operational efficiency.

In addition to ensuring uptime, the failover router’s load balancing feature optimized network performance by distributing traffic across both connections. This approach enhanced overall efficiency and prevented any single connection from becoming overloaded.

As a result, the manufacturer experienced a significant reduction in downtime, increased production efficiency, and improved revenue. The successful implementation of the industrial failover router demonstrated the value of robust redundancy solutions in maintaining continuous operations and protecting against network disruptions.

B. Maintaining Remote Oil & Gas Pipelines: Reliable Communication for Critical Infrastructure

An oil and gas company operating remote pipelines faced challenges in maintaining reliable communication due to the harsh environmental conditions and limited infrastructure availability. To ensure continuous monitoring and control, the company deployed cellular routers with dual SIM support.

These cellular routers provided always-on connectivity by leveraging multiple cellular networks. The dual SIM capability ensured that if one network experienced issues, the router could switch to the other, maintaining continuous communication.

The rapid deployment and scalability of cellular routers allowed the company to quickly establish reliable connectivity across remote sites. This capability was crucial for monitoring pipeline conditions, detecting issues in real-time, and ensuring the safety and efficiency of operations.

The successful deployment of cellular routers enabled the oil and gas company to maintain reliable communication, protect critical infrastructure, and enhance operational efficiency. This case study highlights the effectiveness of cellular routers in providing robust redundancy solutions for remote and challenging environments.

The Future of Industrial Connectivity: Emerging Trends and Advancements

The field of industrial connectivity is continually evolving, with new technologies and advancements shaping the future of network redundancy. By staying informed about these trends, businesses can leverage cutting-edge solutions to enhance their network resilience.

A. SD-WAN (Software-Defined WAN) Technology: Simplifying Network Management

SD-WAN technology is revolutionizing network management by providing a centralized, software-defined approach to routing and managing network traffic. This technology simplifies the management of complex networks, making it easier to implement redundancy and optimize performance.

For example, a manufacturing company with multiple sites can use SD-WAN to manage their network infrastructure from a single interface. This centralized control allows administrators to configure redundancy solutions, monitor performance, and address issues in real-time.

SD-WAN also enhances network flexibility by allowing businesses to leverage multiple connection types, such as wired, cellular, and satellite. This capability ensures continuous connectivity, even in diverse and dynamic environments.

B. Integration with Cloud Platforms: Leveraging Cloud-Based Analytics for Enhanced Visibility

The integration of redundancy solutions with cloud platforms is another emerging trend. By leveraging cloud-based analytics, businesses can gain enhanced visibility into their network performance and make data-driven decisions to optimize their infrastructure.

For instance, an industrial facility can use cloud-based analytics to monitor network traffic, identify patterns, and predict potential issues. This proactive approach allows businesses to implement preventive measures and ensure continuous connectivity.

Cloud integration also enhances remote management capabilities, allowing administrators to access network data and control their infrastructure from anywhere. This capability is particularly valuable for businesses with multiple remote sites, providing real-time insights and control.

In conclusion, emerging trends and advancements in industrial connectivity, such as SD-WAN technology and cloud integration, are shaping the future of network redundancy. By staying informed and adopting these cutting-edge solutions, businesses can enhance their network resilience, ensure continuous connectivity, and protect their operations against the challenges of the modern industrial landscape.

FAQ

Isn’t a single internet connection enough? Why do I need redundancy?

A single internet connection may be sufficient for basic operations, but it poses a significant risk in the event of an outage. Network redundancy ensures continuous connectivity by providing backup connections that automatically take over when the primary connection fails. This capability is crucial for maintaining operations, protecting revenue, and ensuring customer satisfaction.

What are the ongoing costs associated with cellular failover?

The ongoing costs of cellular failover include data usage charges and potential subscription fees for cellular services. However, these costs are often outweighed by the benefits of maintaining continuous connectivity and preventing costly downtime. Businesses should assess their data usage and choose a cellular plan that meets their needs while balancing cost considerations.

Can I use a consumer-grade router for industrial applications?

Consumer-grade routers are not designed to withstand the harsh conditions and demanding requirements of industrial applications. Industrial-grade routers offer enhanced durability, advanced features, and reliable performance in challenging environments. For critical industrial operations, investing in an industrial-grade router ensures continuous connectivity and protects against network disruptions.

How can I ensure a smooth transition during failover events?

Ensuring a smooth transition during failover events requires implementing automatic failover capabilities. This feature allows the backup connection to take over seamlessly when the primary connection fails, maintaining continuous connectivity without manual intervention. Regular testing and monitoring of failover systems also help ensure they function correctly when needed.

What are some reputable vendors of industrial failover and cellular routers?

Several reputable vendors offer industrial failover and cellular routers, including Teltonika, Cisco, Cradlepoint, and Sierra Wireless. These companies provide robust and reliable solutions designed to meet the demanding requirements of industrial applications. When selecting a vendor, businesses should consider factors such as product features, support services, and industry reputation.

What are the main differences between industrial failover routers and cellular routers?

Industrial failover routers are designed for durability and reliability in harsh environments, offering multiple WAN connections for seamless failover. Cellular routers provide untethered connectivity using cellular networks, allowing rapid deployment and scalability. Both offer unique advantages, with industrial failover routers excelling in rugged settings and cellular routers providing flexibility and quick setup.

How can I determine the best redundancy solution for my business?

To determine the best redundancy solution, conduct a thorough network needs assessment, considering bandwidth requirements, critical applications, and potential points of failure. Evaluate the deployment environment, including physical location and infrastructure availability. Balance cost considerations, weighing upfront investment against long-term benefits. Consulting with network specialists can also provide valuable insights and recommendations.

What are some advanced features to look for in redundancy solutions?

Advanced features to look for in redundancy solutions include automatic failover, which ensures seamless transitions during outages; VPN tunneling, which secures communication channels for sensitive data; and remote management, which allows monitoring and controlling the network from any location. These features enhance functionality, reliability, and security, providing robust protection against network disruptions.

Conclusion: Guaranteeing Uptime – The Final Word on Choosing the Right Redundancy Solution

A. Recap: Key Considerations for a Reliable Industrial Network

Ensuring continuous connectivity in industrial environments requires careful consideration of network needs, deployment environments, and cost factors. By assessing these aspects and choosing the right redundancy solution, businesses can protect their operations, maintain productivity, and prevent costly downtime.

B. The Importance of Consulting with Network Specialists

Consulting with network specialists is crucial for selecting and implementing the right redundancy solution. These experts can provide valuable insights, recommend the best technologies, and ensure that the chosen solution meets the specific needs of the business. Their expertise helps optimize network performance and reliability.

C. Investing in Uptime: Peace of Mind for a Connected Future

Investing in robust redundancy solutions provides peace of mind by ensuring continuous connectivity and protecting against the risks of network downtime. By implementing advanced features and staying informed about emerging trends, businesses can enhance their network resilience and secure their operations for a connected future.

In conclusion, choosing the right redundancy solution is essential for maintaining continuous connectivity in industrial environments. By considering network needs, deployment environments, and cost factors, businesses can select the best solution to ensure uptime and protect their operations. Investing in redundancy solutions provides long-term benefits, including increased productivity, reduced downtime, and enhanced operational efficiency.