I. Introduction: The Power of Remote PLC Access

In today’s fast-paced industrial world, remote access to PLCs isn’t just a luxury—it’s a necessity. Imagine being able to monitor, control, and troubleshoot your industrial operations from anywhere, whether you’re in the office or on a different continent. With remote PLC management, businesses can improve efficiency, reduce costs, and gain flexibility that was previously unimaginable. But, with great power comes great responsibility, and remote access introduces new security concerns and network complexities that require careful planning and robust solutions.

In this guide, we’ll walk you through how to set up an industrial VPN router for secure PLC access. Whether you’re overseeing a massive factory or managing a small network of industrial devices, this guide will help you maximize your system’s potential while keeping security at the forefront.

II. Understanding VPN Routers: The Backbone of Remote PLC Access

A. What is a VPN Router?

At the heart of remote PLC access is the VPN router—a specialized device that allows secure communication between your PLC and remote devices. Unlike regular consumer-grade routers, industrial VPN routers are built for demanding environments and offer features designed for industrial applications. These routers create secure, encrypted tunnels over the internet, protecting sensitive data from cyber threats.

A VPN router essentially acts as a gatekeeper, ensuring that only authorized personnel can access your network. It offers a secure and reliable way to connect to your PLC, no matter where you are.

B. Key Features of Industrial VPN Routers

Industrial VPN routers come with a range of features that make them ideal for remote PLC access. These include:

- Robust hardware designed to withstand harsh industrial environments

- Advanced security features like encryption protocols, firewall protection, and intrusion detection

- Support for multiple VPN protocols such as OpenVPN, IPsec, and L2TP/IPSec

- Redundancy and failover options to ensure continuous connectivity

- Remote management and monitoring capabilities

These features ensure that your remote access setup is not only functional but also secure and reliable.

III. Choosing the Right VPN Router for PLC Applications

Selecting the right VPN router for your PLC applications can be overwhelming, given the variety of options available. Here’s how you can make the right choice.

A. Factors to Consider

When choosing a VPN router for your PLC, consider the following factors:

- Performance: The router should be able to handle the data throughput required by your PLCs.

- Security Features: Look for routers with advanced encryption protocols, strong firewall settings, and intrusion detection.

- Compatibility with PLC Protocols: Ensure that the router supports the communication protocols used by your PLCs, such as Modbus or Ethernet/IP.

- Reliability: In industrial settings, downtime can be costly. Choose a router that offers redundancy and failover options to ensure uninterrupted access.

- Scalability: As your operations grow, your network needs to grow with it. Choose a router that can scale with your needs.

B. Popular VPN Protocols for PLC Access

Not all VPN protocols are created equal. Here are some popular options for PLC access:

- PPTP: An older protocol, PPTP is easy to set up but less secure compared to modern options.

- L2TP/IPSec: This combination provides better security by adding an extra layer of encryption.

- OpenVPN: Known for its flexibility and high level of security, OpenVPN is a popular choice for industrial applications.

- Site-to-Site VPN: This is ideal for connecting entire networks at different locations, ensuring secure communication between PLCs across multiple sites.

Each protocol has its strengths and weaknesses, and the best choice depends on your specific needs.

IV. Essential Components for Setup: Hardware and Software Requirements

To set up remote PLC access using a VPN router, you’ll need a few key components.

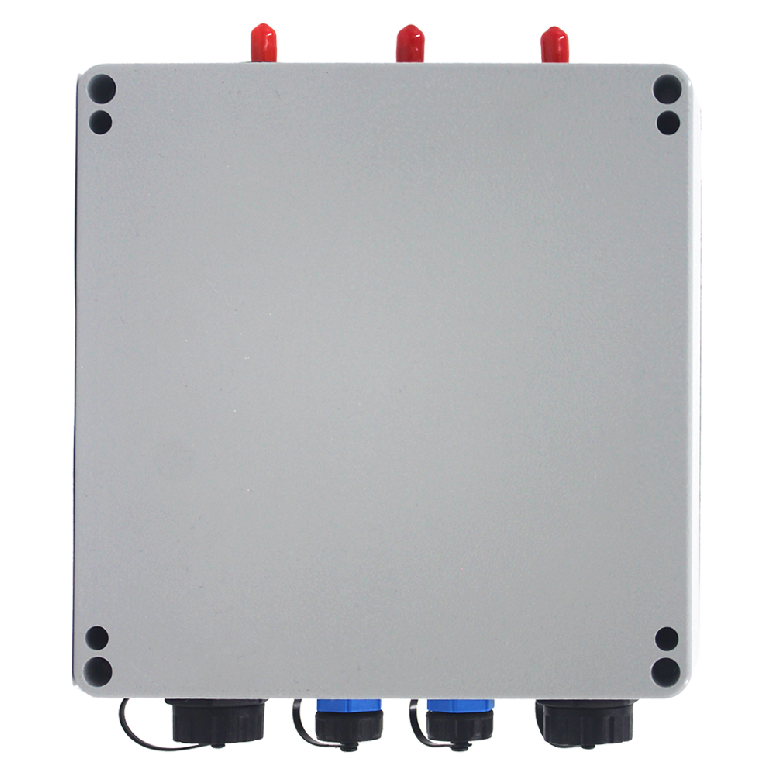

A. Industrial VPN Router

At the core of your setup is the industrial VPN router. Choose a device that is designed for rugged environments and can handle the demands of an industrial network.

B. PLC (Programmable Logic Controller)

Ensure your PLC is compatible with VPN connectivity. Modern PLCs typically support network communication protocols that can work seamlessly with VPN routers.

C. Network Infrastructure

Your network setup will need to include Ethernet cables, switches, and internet connectivity. Make sure your infrastructure is robust enough to handle the data traffic between your PLCs and remote access points.

V. Step-by-Step Configuration: A Detailed Guide

Now that you’ve chosen your components, it’s time to set everything up. Here’s a step-by-step guide to configuring your VPN router for PLC access.

A. Initial Setup

Start by physically connecting the hardware. Plug in your VPN router, connect it to the internet, and power it on. Ensure that your PLC is connected to the same network as the router.

B. Network Configuration

Next, configure your network settings. Assign IP addresses to your devices and set up the appropriate subnets. This ensures that all devices on your network can communicate with each other.

C. VPN Configuration

Configure the VPN settings on your router. Choose your preferred VPN protocol (e.g., OpenVPN, L2TP/IPSec) and set up the necessary encryption and security protocols. Create VPN tunnels that will allow remote access to your PLC.

D. PLC Configuration

On the PLC side, enable VPN connectivity and set access permissions. This will allow authorized remote users to connect to and manage the PLC.

E. Testing Connectivity

Finally, test the setup by attempting to access the PLC remotely. Ensure that all VPN tunnels are functioning correctly and that the PLC is responsive to remote commands.

VI. Security Considerations: Protecting Your PLC Network

Security is paramount when setting up remote access to your PLC network. Here are some key security measures to implement:

A. Strong Password Policies

Use complex and unique passwords for all devices on your network. Avoid using default passwords, as they are easily exploited by hackers.

B. Encryption Protocols

Ensure that all data transmitted between your PLC and remote access points is encrypted. Choose secure encryption algorithms like AES-256 to protect sensitive information.

C. Firewall Rules

Implement strict firewall rules to control incoming and outgoing traffic. Only allow authorized devices to connect to your network.

D. Regular Updates

Keep your router’s firmware and PLC software up-to-date. Regular updates often include important security patches that protect against newly discovered vulnerabilities.

VII. Troubleshooting Common Issues: Resolving Connectivity Problems

Even with careful setup, you may encounter issues with your remote PLC access. Here’s how to troubleshoot common problems:

A. Network Connectivity

Check that all cables are properly connected and that network settings (e.g., IP addresses, subnets) are correctly configured.

B. VPN Configuration

If your VPN tunnel isn’t working, double-check your VPN settings. Ensure that the correct protocol is selected and that encryption settings are configured properly.

C. PLC Configuration

Verify that your PLC’s network settings are correct and that it is properly configured to allow remote access.

D. Firewall Interference

If your firewall is blocking access, review your firewall rules and make sure that the necessary ports are open.

VIII. Advanced Features: Enhancing Remote PLC Access

Once you’ve set up the basics, you can enhance your remote PLC access with these advanced features:

A. Dynamic DNS

Use Dynamic DNS to ensure that your remote access points can always resolve the correct domain name, even if your IP address changes.

B. Load Balancing

Distribute network traffic across multiple VPN tunnels with load balancing to ensure consistent performance and reliability.

C. Quality of Service (QoS)

Implement Quality of Service settings to prioritize PLC traffic, ensuring that critical commands and data are transmitted in real time.

IX. Case Studies: Real-World Applications of Remote PLC Access

The real power of remote PLC access becomes evident when looking at its applications in various industries. By connecting PLCs to VPN routers, businesses have been able to monitor, control, and troubleshoot systems remotely. Let’s explore some real-world case studies that highlight the transformative benefits of remote PLC access.

A. Remote Monitoring and Control of Industrial Processes

In manufacturing, remote PLC access has revolutionized how operations are managed. Take, for example, a large automotive parts manufacturer with multiple production lines spread across several facilities. Traditionally, the company had to rely on onsite technicians to monitor and control the PLCs managing the assembly lines. However, downtime due to machine failure or process disruption was a significant issue, often leading to delays in production schedules.

By implementing industrial VPN routers and enabling remote PLC access, the manufacturer transformed its operations. Engineers and technicians could now monitor production lines from a central location, gaining real-time insight into the performance of each machine. This allowed them to detect issues before they caused downtime, as well as adjust parameters to optimize the production process.

The benefits were clear:

- Reduced downtime: Early detection of potential issues allowed for preventive maintenance, significantly reducing unplanned downtime.

- Increased productivity: By remotely adjusting production parameters, the company was able to optimize processes and increase output.

- Cost savings: With fewer onsite technicians required, labor costs were reduced, and maintenance schedules became more efficient.

In addition, the manufacturer could leverage historical data from PLCs to identify patterns in machine performance, leading to further improvements in efficiency and reliability.

B. Troubleshooting and Diagnostics from Off-Site Locations

Remote PLC access also shines in industries where quick troubleshooting is essential to avoid costly downtime. A power utility company that manages a network of substations across a wide geographic area offers a prime example. Each substation relies on PLCs to control the distribution of electricity and ensure the stability of the grid.

Before implementing remote access via VPN routers, troubleshooting issues at these remote substations required dispatching field technicians to physically inspect and diagnose problems. This process was not only time-consuming but also expensive, as it often involved significant travel time and emergency callouts during off-hours.

By connecting the PLCs at each substation to industrial VPN routers, the utility company enabled remote diagnostics. Now, engineers can monitor the status of each substation from the central control room. If a problem arises, they can remotely access the PLC, identify the issue, and in many cases, fix it without ever having to send a technician on-site.

The outcomes were impressive:

- Faster response times: Remote access allowed engineers to diagnose and address issues in minutes, rather than hours, reducing the risk of extended outages.

- Lower operational costs: With fewer emergency callouts and reduced travel expenses, the company saved significantly on operational costs.

- Improved grid stability: By maintaining consistent oversight of PLCs, the utility could proactively manage the grid, minimizing the risk of disruptions and improving overall reliability.

This remote troubleshooting capability proved invaluable during extreme weather events, when rapid response times were critical to maintaining service for thousands of customers.

C. Emergency Response and Crisis Management

Remote PLC access has also proven to be a game-changer in emergency response situations. A chemical processing plant provides a compelling example. In this high-risk environment, the plant’s PLCs control critical systems such as chemical reactors, safety alarms, and ventilation. A failure in any of these systems could have catastrophic consequences.

In the past, emergencies required onsite personnel to manually shut down systems or adjust parameters, often putting them in dangerous situations. The plant recognized the need for a safer, more efficient solution, which led them to implement industrial VPN routers for remote PLC access.

When an unexpected leak occurred in one of the reactors, the plant’s engineers were able to remotely access the PLC controlling the affected system from a safe location. Within moments, they were able to shut down the reactor, activate safety protocols, and vent the affected area. This rapid response minimized the risk to both personnel and the surrounding environment.

Key results included:

- Enhanced safety: Remote access reduced the need for personnel to be physically present in hazardous areas during emergencies.

- Faster incident resolution: Engineers could immediately respond to issues, significantly reducing the potential for escalation.

- Minimized downtime: After the incident, engineers were able to remotely restart systems and resume operations much more quickly than would have been possible with manual intervention.

The plant’s crisis management capabilities were dramatically improved, and the ability to remotely control critical systems became a core part of their safety protocols.

X. FAQ

A. Can I use a consumer-grade VPN router for PLC access?

Consumer-grade VPN routers are generally not recommended for industrial PLC access due to their lack of advanced security features and durability in harsh environments.

B. What are the security risks associated with remote PLC access?

The primary security risks include unauthorized access, data breaches, and disruption of industrial operations. Using a secure VPN router with strong encryption and firewall settings can mitigate these risks.

C. How can I ensure the reliability of my VPN connection?

To ensure a reliable connection, use a router with redundancy and failover options, regularly update firmware, and monitor network performance.

D. What is the cost involved in setting up a VPN router for PLC access?

The cost depends on the complexity of your network, the type of VPN router you choose, and any additional hardware or software needed. However, the investment often pays off through increased efficiency and reduced downtime.

E. Can I use a cellular network for remote PLC access?

Yes, industrial VPN routers with cellular backup can provide remote PLC access over cellular networks, making them ideal for remote or hard-to-reach locations.

XI. Conclusion: The Power of Remote PLC Access

In summary, setting up an industrial VPN router for remote PLC access can dramatically improve your operational efficiency, flexibility, and security. By following best practices for configuration and security, you can protect your network from cyber threats while ensuring reliable, real-time control over your industrial processes. As technology continues to evolve, the future of remote PLC connectivity will only become more advanced, offering even greater opportunities for innovation and growth.