Breaking the Shackles of Traditional Energy Management in Large Industrial Parks

Traditional energy-management models reveal their obsolescence the moment they meet a modern, multi-purpose industrial park. The most visible pain-point is manual meter reading: hundreds of scattered meters must be visited one by one, burning labor hours and introducing human error that keeps data-inaccuracy rates stubbornly high. Unreliable figures rob managers of any solid basis for planning or dispatching energy.

Equally serious is the blindness to critical loads. Lifts, water pumps and chillers account for a large share of consumption, yet they are rarely metered in legacy systems. Energy is wasted invisibly—elevators running empty at off-peak, pumps spinning at fixed speed against throttled valves—because there is no data trail to expose the waste.

Aging HVAC billing systems distort usage and trigger tenant complaints, while underground leaks go undetected until sinkholes or burst pipes drive up O&M costs.

From Blindness to Full-Site Perception

The first step toward intelligent energy is full-site perception. Smart sensors are deployed across the park to create a multi-layer energy-sensing network.

-

Power: smart meters stream voltage, current, power and power-quality in real time. Load-duration curves expose peaks and valleys, enabling time-of-use optimisation.

-

Water: ultrasonic smart water meters measure instantaneous flow and accumulated volume; leak-detection algorithms flag anomalous night-time flow within minutes. Inline pH and turbidity probes guarantee water quality.

-

Gas: diaphragm smart gas meters log hourly consumption and shut off automatically when seismic or methane-leak sensors trip.

-

Thermal: BTU meters on chilled-water and steam circuits feed COP calculations for every chiller plant.

Intelligent Control – Turning Data into Decisions

Once high-granularity data is available, an AI-driven control layer can:

-

Build predictive models that merge calendar bookings, weather forecasts and historical loads to forecast tomorrow’s demand curve within ±3 %.

-

Optimise HVAC set-points every 15 minutes based on occupancy counters, CO₂ sensors and electricity price signals, typically shaving 12–18 % off cooling energy.

-

Dispatch lifts intelligently: during lunch peak, cars adopt “express” patterns; at 2 a.m. half the bank sleeps, cutting standby consumption by 30 %.

-

Detect anomalies: a 20 % overnight spike in one feeder triggers an alert; the system pinpoints a rogue bitcoin miner hidden in a storage room.

Alotcer IoT Gateways – the Nerve Nodes

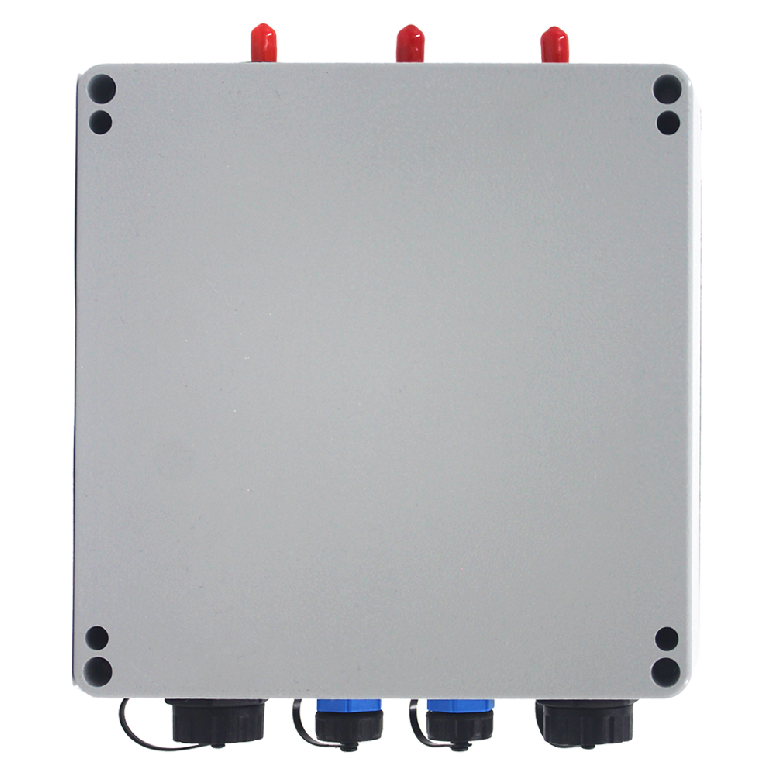

Alotcer AR/IG series industrial IoT gateways sit between sensors and the cloud, acting as protocol translators, edge computers and secure routers.

-

Universal connectivity: RS-485 (Modbus, DLT-645, CJ-188), M-Bus, LoRa, NB-IoT, 4G/5G, Wi-Fi 6, Ethernet. One gateway can talk to 128 meters simultaneously.

-

Edge intelligence: ARM Cortex-A55 quad-core CPU with 1 TOPS NPU runs real-time anomaly detection; only meta-data or alarms are sent upstream, saving 70 % of data traffic and slashing latency to <200 ms.

-

Secure pipeline: TLS 1.3, X.509 certificate, AES-256 hardware crypto, VPN failover and IEC 62443-4-2 secure-boot chain.

-

Zero-touch O&M: TR-069, MQTT and Alotcer Cloud allow remote firmware upgrades, parameter tweaks and log retrieval—no scaffolding, no scissors-lift, no site visit.

Results – a New Energy Paradigm

By combining full-site perception, AI-based control and Alotcer’s rugged gateways, an industrial park can:

-

Cut total energy consumption 15–25 % and water losses by 40 %.

-

Reduce manual meter-reading staff from 20 to 2.

-

Settle HVAC billing disputes to near zero with tamper-proof hourly data.

-

Shorten leak-repair time from weeks to hours, avoiding road subsidence and safety incidents.

-

Qualify for ISO 50001 certification and green-bond financing, boosting both ESG score and asset value.

In short, the park graduates from reactive fire-fighting to predictive, data-driven energy leadership—sustainable, competitive and ready for the next decade.